Composite materials usually have a long useful life, as well as being lighter, stronger and more flexible than traditional products.

Composite materials is the name that experts in materials science give to elements made up of at least a couple of components that can be separated from each other with mechanical procedures and are easily distinguished individually. Composites , as they are usually described, are resources with a great presence in the world of construction and in the automotive industry , for example.

It is constructive to indicate that there are different procedures to obtain them. It is common to resort to molding techniques and curing and finishing methods , as well as lamination processes . As noted by deepening the knowledge around these issues, a curing process begins with details about reinforcement ( sheets , fibers or particles ) and matrix (since it can be a polymer matrix, a ceramic or a metallic one and then you need to know how to act and treat it). Among other items, the weight of the matrix, what dimensions the reinforcement has, what temperatures are needed and what mechanical properties are targeted are considered. Injection molding , resin transfer molding (RTM) , pultrusion , and lamination (both manual and automatic) are other useful alternatives for manufacturing composite materials .

It is important to highlight that, due to the benefits and unique characteristics they present, the majority of these products arise artificially after several trials through trial and error. In recent years, furthermore, research and projects have emerged that are aimed at the development of ecological or sustainable composite materials . Of course there are exceptions: bones and wood are composite materials of natural origin.

Classification of composite materials

Composite materials are divided into multiple categories based on their particularities.

On the one hand there are structural composite materials , which in turn are segmented into sets of monolithic structures and sandwich panels. There are also particle-reinforced composite materials , fiber-reinforced composite materials and dispersion-hardened composite materials .

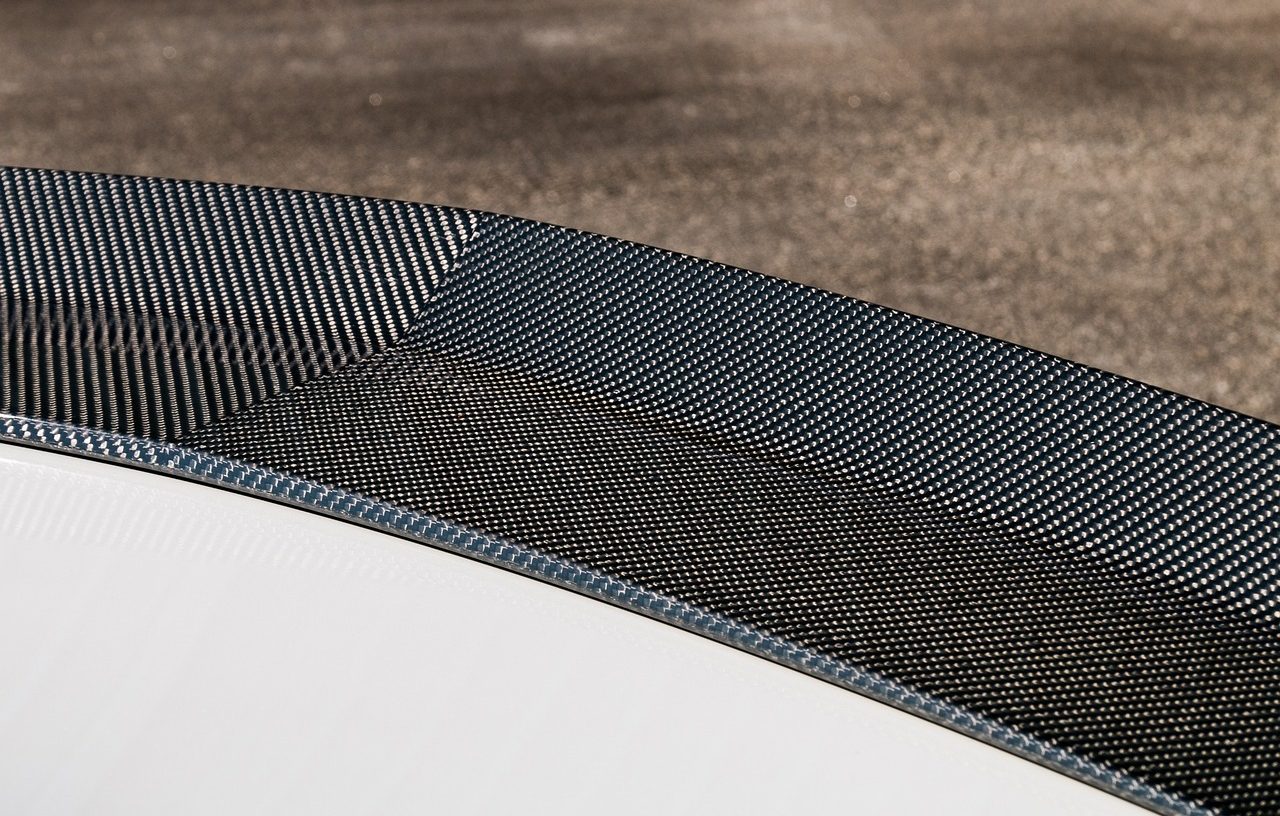

It should be noted that, if fibers are used, they can be ceramic, metallic, natural, carbon, glass, etc. As for the matrices , within the organic options, elastomers , thermostable matrices and thermoplastic matrices appear as possibilities.

Thanks to the advancement of technology and scientific experimentation , in recent decades it has also been possible to develop intelligent composite materials that stand out for their versatility and their ability to recover after being exposed to some type of damage. It should also not be overlooked that, by appealing to plant fibers , a group of experts managed to obtain composite materials with a renewable profile. The objective of the project that brought together several scientists was the creation of novel nanomaterials that could be composite and natural .

In the construction industry, we usually work, for example, with concrete, as a composite material that arises from the combination of multiple elements is known.

Properties

Composite materials are highly valued for the properties that characterize them. When compared to traditional products, composites generally show a higher level of lightness , resistance or flexibility .

Specialists in the field often extol, for example, the mechanical properties of composite materials based on a polymer matrix . Their physical properties and resistance to corrosion also stand out.

Of the fiber-reinforced compounds , which are designed in such a way as to achieve the best possible relationship between strength and weight , the great resistance they show in terms of material fatigue is estimated. You should always take into account the desired result and educate yourself about the particularities of the components since, according to certain reports, the thermal conductivity coefficient of a composite material designed with fiberglass is low, to list one case. indicative way.

Broadly speaking, it can be noted that a composite material usually has a low density and high resistance . Their advantages also include their durability and the simplicity of their maintenance since they are able to withstand variations in humidity, temperature, etc. without ruining or corroding.

Carbon fiber, for example, is a composite material that has gained great prominence within the automotive industry.

Examples of composite materials

Examples of composite materials can be found in numerous areas since they have a wide field of application . It must be admitted that, sometimes, the costs or pace of manufacturing make access to certain composite materials difficult, especially if they are the most innovative or modern.

From the combination of ceramic and metal, specifically, cermet is born, a word that refers to a product created from a ceramic element combined with a certain metal that, due to its composition, brings together the tenacity of metals and the hardness of a ceramic.

Concrete , to name another composite material , is made from a mixture of water, chemicals, coarse and fine aggregates and cement, and is intended for construction works.

Plywood (or plywood ), adobe and pykrete are other products that make up the list of composite materials .