A lathe is a machine that is based on the rotation of a cylinder.

A lathe (from the Latin tornus , which in turn comes from a Greek word meaning "turn" or "turn" ) is a machine composed of a cylinder that rotates around its axis by the action of wheels or levers , and that acts on resistance through a rope that is wound around the cylinder.

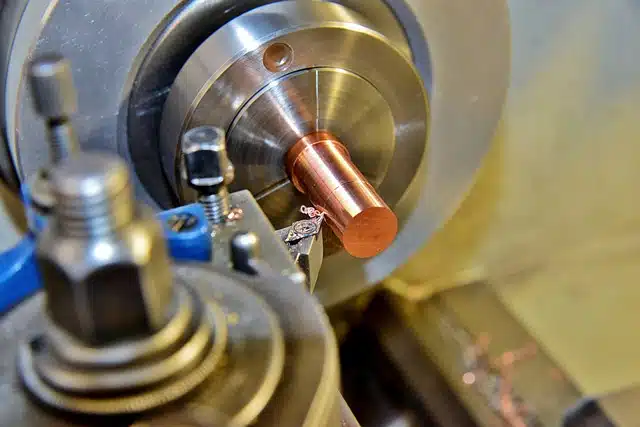

In the metallurgical industry , the lathe is the tool that allows machining geometrically shaped parts . These devices are responsible for rotating the part while other cutting tools are pushed against its surface, allowing the chip to be cut according to the required conditions.

The metallurgical lathe has two working axes. The cutting tool moves on rails parallel to the axis of rotation of the piece (the Z axis ), while, on these rails, there is another carriage that moves in a radial direction to the piece being turned (that is, on the X axis ).

Lathe in pottery and dentistry

In pottery , the wheel is a traction machine (human or electrical) that has a platen welded to a shaft. Said shaft rotates at an adjustable speed. The potter models the clay or ceramic paste on the platen while the shaft does not stop rotating.

The dental drill , invented in 1863 by George Harrington , is one of the most used tools in dentistry . It was created by adapting the mechanism of a wind-up clock so that a small wick rotates and works on the teeth.

In pottery, the wheel allows the clay to be molded.

Other type of device

A revolver lathe is known as one that is designed with the objective of machining parts that can be worked on simultaneously with various tools. With its help, the time to complete a job is considerably reduced. The pieces it uses have an appearance similar to that of a bushing (tubular in shape and made of bronze, plastic or steel). When you can hold the bar correctly, you proceed to turn it in different ways on its interior and exterior parts.

The various tools used to machine parts on a turret lathe are placed on a carriage that has a hexagonal-shaped rotating turret. It is also possible to work individually, fixing the pieces to a claw plate that is activated by a hydraulic mechanism.

The automatic lathe

The automatic lathe allows the work to be carried out absolutely automatically , both the machining and the feeding of the bar that is needed for each of the pieces. A possible classification distinguishes between automatic lathes:

* a single spindle : they are mainly used to machine small parts that need to be produced in large series;

* multi-spindle : also called multi-spindle , they are used when the size of the parts is considerable and allows programming the machining that is desired to be carried out on each part of them. Since all pieces inserted simultaneously must be worked in the same way, the time saved in these cases represents a great advantage over manual lathes.

Despite the benefits that automation offers, it is important to note that it requires a lot of maintenance work on the part of operators, which is why they are often used, especially in mass production.

More tools

The vertical lathe , on the other hand, has a vertical axis and was created for the machining of pieces of considerable size and difficult to manipulate in a horizontal position. Unlike the latter, since the pieces rest on the plate, a clamping system is not required. Bridge cranes, among other tools, are used to move and fix the pieces.

The brake of some carriages and the turnstile are also called winches.