It is common for devices to be installed in the kitchen to promote air recirculation.

Recirculation is a concept that comes from circulation , a term that refers to the process of circulating . Circulation, for its part, is associated with movement, transit or traffic, whether of vehicles, currencies, fluids, etc.

The concept of recirculation is linked to boosting the circulation of something within the same circuit or system . Air, water and blood, for example, are some of the things that can be recirculated.

Types of recirculation

Air recirculation can be developed in a kitchen . There are hoods that absorb air, filter it and then expel it again, always within the same environment. In this way, the air is never sent to the outside. The case of extraction is different, which consists of capturing air from the kitchen to expel it from the environment.

There are buildings, on the other hand, that have hot water recirculation systems. This allows hot water to emanate from the faucet immediately, since high-temperature water constantly circulates through the pipe. To achieve this recirculation, a pump is installed that constantly carries cold water to a heater and then back to the pipe. This way the water is always hot.

In the field of medicine , we speak of recirculation when, in a dialysis process, the blood that has already been dialyzed passes through the dialyzer again. This implies that dialysis loses effectiveness, since it is carried out again on already treated blood.

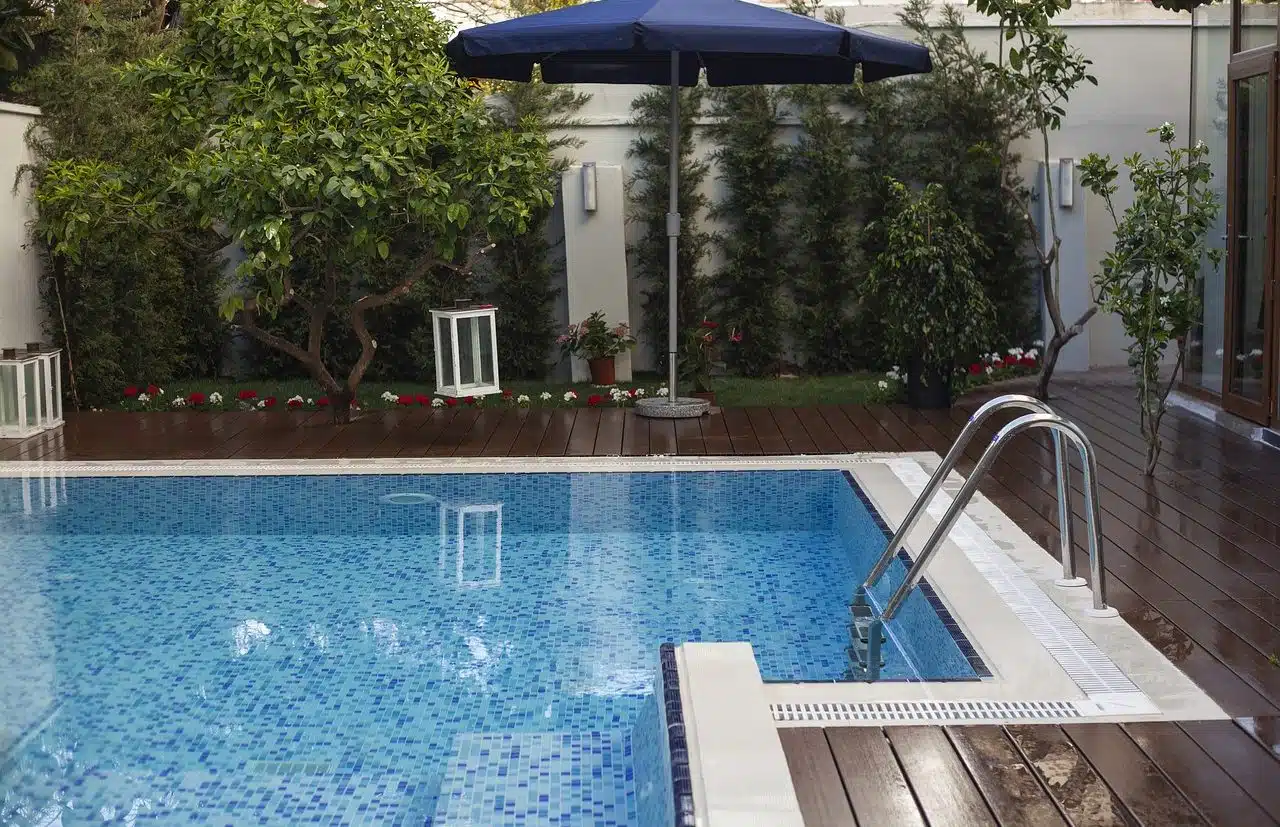

Water recirculation time is an important variable in the dynamics of a pool.

The concept in swimming pools

There is a concept associated with swimming pools called water recirculation time or, in English, turnover , and it is the time in hours that a given purification system takes to treat an amount of water equivalent to the volume of the pool at which it is treated. that is connected. This value is related to several factors, which must be known to understand why it is high, low or acceptable, depending on the case.

For example, two fundamental points to take into account to know how efficient purification equipment can be are the dimensions of the pump and the filter, which are the two basic components of a simple system; If the pump has a high flow rate but the filter is small, the time will not be proportional to the size of the pump, since the filter will not be able to take advantage of its capacity, and the same would happen in the opposite case.

Recirculation in a chemical reactor

Another area in which recirculation takes place is a chemical reactor , a device capable of hosting a specific chemical reaction . It has a design that maximizes the selectivity and conversion of the reaction, seeking the lowest possible cost. Among the different types of chemical reactor is the plug flow reactor with recirculation .

First, plug flow reactors (also known by their acronym PFR ) operate in a stationary manner; That is, its properties at a given moment are maintained over time. Reactors that include recirculation without a separation device take a portion of the output stream and direct it towards the equipment inlet, so that mixing is favored (in fact, the benefits are greater the greater the recirculation).

It is important to note that in a perfectly mixed reactor, which does not provide an outlet stream, recirculation would offer no advantage, since mixing would have been completed by the time the system wanted to divert part of the flow . A concept related to these devices is the recirculation ratio , which is symbolized by the letter R , and is defined as the ratio between the flow that returns and the flow that leaves.