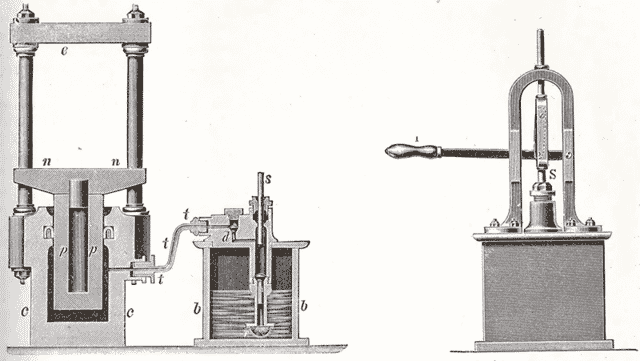

Schematic of an old hydraulic press

The term press , which derives from the Catalan word premsa , has several uses. On this occasion we are interested in its meaning as the machine that is used to compact or compress something .

General characteristics

Hydraulic , meanwhile, is an adjective that is used to describe what moves or moves through a fluid . Generally the notion is linked to water .

From these ideas, we can move forward with the definition of a hydraulic press . This is the name given to a mechanism that has communicating vessels and water pistons : with a slight force applied to the piston that has a smaller area, a greater force is achieved in the piston with a larger area.

The hydraulic press, in this framework, has two cylinders filled with water or oil that are connected to each other; In each one, pistons of different area are adjusted that are in contact with the fluid. By exerting a force on the piston of smaller area or section, a pressure is created in the water that is transmitted in its entirety to the rest of the fluid and reaches the other piston.

A hydraulic press, in short, allows forces to be multiplied , obtaining large forces from small forces. This type of machine is usually used to lift heavy bodies .

Advantages of hydraulic press

Unlike the mechanical press, the hydraulic press allows the total force to be maintained throughout the entire stroke and not just at the end. This way, it is not necessary to calculate the pressure at the beginning since nothing is lost in the entire process. It also offers greater capacity at a lower price, with possibilities such as installing larger platens on relatively small presses.

The advantage of its price compared to the mechanical press is related precisely to its resulting power, which makes it unbeatable in the comparison. It is also cheaper to maintain , since it has few moving parts, a simple design, and is kept lubricated with oil fluid. Potential problems are usually easy to solve, unlike what a breakdown in a mechanical press can cause, both in the time required and in the impact on production.

It also includes a safety valve for the highest force value it supports, so that once calibrated there is no risk of damaging a die or even causing damage to the structure itself.

Disadvantages

Its speed is one of its weak points compared to the mechanical press, which always surpasses it in this aspect. Another of its disadvantages lies in the need for an external force to feed the raw material , which must be integrated with the general control system. In any case, there is more than one option on the market for this part, such as air, hitch or rolls.

Finally we can mention a problem that occurs in both the hydraulic and mechanical press: during the punching process, there is a shock after the start. Hydraulics are more demanding, because they must have an isolator so that decompression does not cause damage to the connections and lines.

Hydraulics allow us to take advantage of the power of water

Pascal's law

The operation of the hydraulic press is based on the so-called Pascal's law , postulated by the Frenchman Blaise Pascal in the 17th century . According to Pascal , the pressure exerted on a fluid that is contained in a non-deformable container is transmitted with identical intensity at all points of the fluid and in all directions. This means that, from small forces, much larger forces can be achieved.