The Kanban method optimizes resource management.

Kanban is a methodology that uses visual resources to manage production and workflow in general. The term comes from the Japanese language and refers precisely to a visual signal.

The term refers to both the visual management system through the so-called Kanban board and the process optimization method that is based on this resource for just-in-time delivery, thus achieving waste reduction and greater operational efficiency . In both cases, the idea is associated with the coordination of actions and teamwork.

Origin of Kanban

The origin of Kanban is found in the late 1940s , when Japanese engineer Taiichi Ohno devised a new management method for Toyota , the company for which he worked. Starting from the Just-In-Time manufacturing philosophy, Ohno proposed producing according to demand (and not manufacturing to introduce products to the market and thus generate demand). Within this framework, the engineer devised Kanban cards to keep inventory at low levels: each card signaled the need for a new product and thus promoted the start of the production process of the item in question.

Over time, the Kanban methodology was adapted to multiple processes and sectors. In the software industry, for example, it has been common since the beginning of this century.

Kanban helps to do bottleneck analysis.

Its characteristics

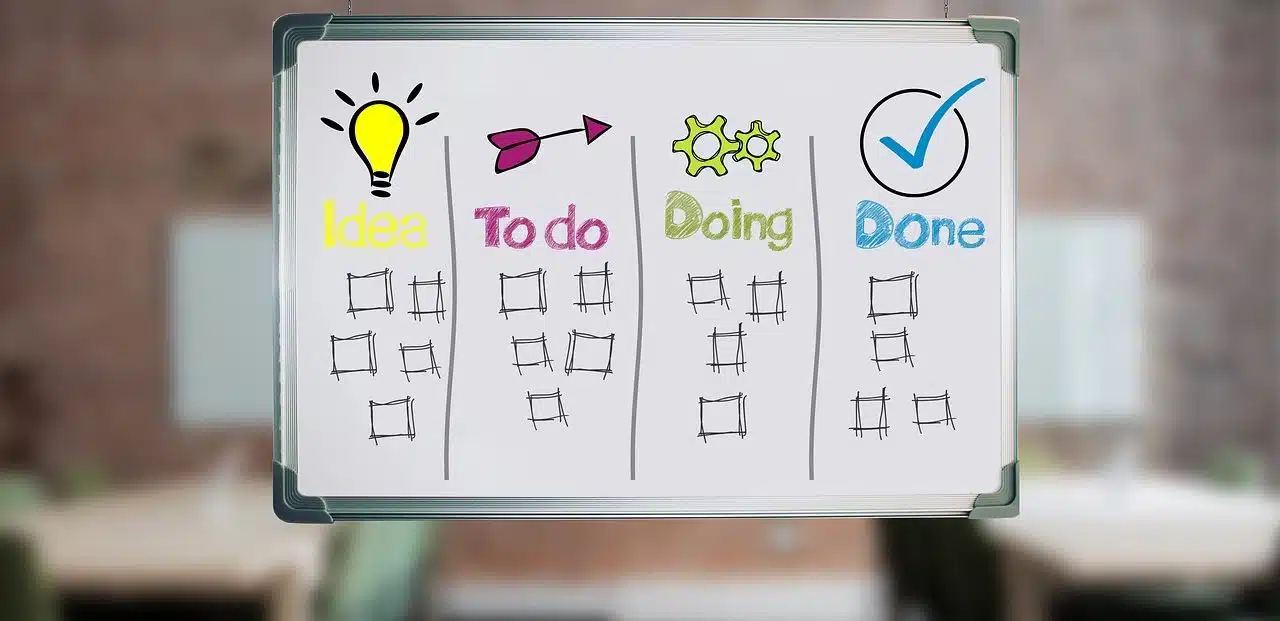

A Kanban board is an instrument that facilitates the visualization of tasks and contributes to an agile development process. Their cards aim to maximize efficiency, avoiding unnecessary tasks.

Through inventory and supply chain control , Kanban allows you to adjust production systems and carry out successful demand management. Also, through task prioritization and data-driven decision making, it drives continuous improvement .

Although there are multiple types and adaptations, the basic operation of the Kanban method in production is as follows: when a purchase or order is made in the storage sector, the signal is transmitted to the beginning of the assembly or manufacturing line for the production of a new item. In this way, the production process is governed by demand and the so-called pull systems (it is the customer who requests the product).

The important thing is that the signal (which can be a card or another element) causes the movement that generates the production of a new unit. The analysis of the circulation of signals, in turn, allows us to identify problems or areas that need some type of intervention.

The Kanban methodology contributes to the improvement of business processes.

Types of Kanban

Kanban boards can be both physical and virtual . In the first case, the usual thing is for the board to be a blackboard or billboard divided into columns, with sticky notes as signs. These signals move according to the progress of the workflow.

A basic physical dashboard might feature three columns: “To Do,” “In Progress,” and “Completed.” The first column records the tasks that must be carried out, the second those that are in progress and the third those that have already been done. The movement of the signs or notes along the board is essential.

The digital Kanban board shares that logic. It is a computer program or platform that can be used asynchronously and remotely so that team members can access it from anywhere and whenever they need it.

Other types of Kanban arise depending on the specific scope of application of the method. In this sense we can speak of production Kanban , order Kanban , transportation Kanban , etc.

Its principles

The implementation of Kanban is based on a series of principles or rules. One of these postulates indicates that one should start with what will be done now: that is, the methodology can be applied to current processes, without having to start from scratch .

Starting from this basis, Kanban requires a commitment to gradual and progressive changes . The work team must commit to evolutionary changes so that the system improves gradually but firmly. Specialists maintain that abrupt modifications are more likely to fail.

Another Kanban principle is respect for processes and roles: each team member has to accept responsibilities and integrate into the structure according to their position. However, another of the implementation rules of the Kanban method admits that leadership is not exercised only in a hierarchical and descending manner, but that leadership must coexist at the various levels of the organization that contribute to the general direction.

Kanban Examples

We can find examples of Kanban in multiple contexts. At one company they can stick cards on the containers and then remove them when the container is used. In this basic Kanban method, cards are signals that reveal the development of the production process and ensure proper replenishment.

Let us now take the case of a small company that launches a new project. In order to facilitate the visualization of tasks, a physical Kanban board is installed where it is detailed with adhesive posters who must perform each task, what phase the work is in and what deadlines to meet.

If we think about a recruitment process, the Human Resources department can take charge of its management with a digital Kanban board . The virtual cards would represent each applicant, which advance in the columns that indicate the stages of the process (CV analysis, interview, reference consultation, job offer, hiring).

Another example of Kanban can be found in a sales office . The dashboard, in this case, can show the progress from the generation of a potential client to the completion of the operation, passing through the different stages of contact and negotiation.