Fusibility is the predisposition of a substance to be melted.

Fusibility is the condition of a fuse : that it can melt ( melt ). Therefore, the fusibility of a material refers to the predisposition it shows to melt or melt.

Possibility of melting

By knowing the fusibility of something, the possibility of producing castings is determined. In this framework, the melting point is key, which is the temperature at which a substance goes from the solid state to the liquid state.

The lower the melting point, the greater the fusibility. If the melting point is very high, on the other hand, the material is said to be refractory . That is why a refractory material has poor fusibility.

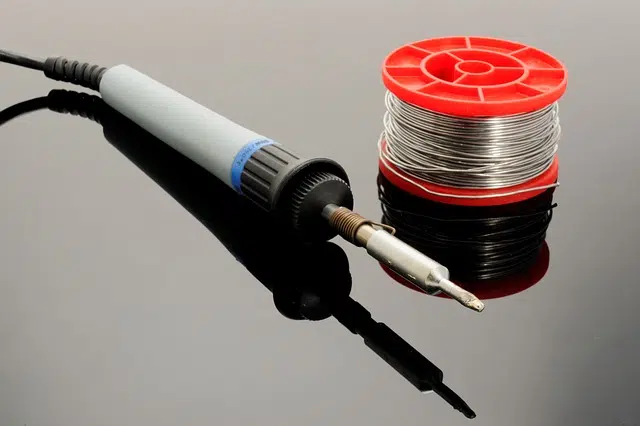

Suppose a person wants to perform welding . To achieve its objective, it needs to work with high fusibility materials, with a low melting point. In this way, by applying heat , you will be able to melt and weld them, fusing them.

We must say that fusibility is important in many areas. Heavy industries , blacksmithing and engineering often take this property of materials into account.

Melting point

As we have seen in the previous paragraphs, knowing the melting point is key to determining the fusibility of a material. In this case, the melting point value is inversely proportional to the fusibility . We can say that this concept is defined as the temperature necessary for a substance to go from a solid to a liquid state.

When the material is precisely at this point, its solid and liquid phases are in complete equilibrium. The factor on which this point depends is the pressure, and it is usually specified taking as reference a normalized pressure condition , such as 100 kilopascals (kPa) or 1 atmosphere. If the direction of change is the opposite, that is, the material goes from liquid to solid, then it is called freezing point .

While almost all known substances have the same temperature value for their melting and freezing points, there are some exceptions. In the first group we find mercury, which in both cases must be brought to -38.8 degrees Celsius; In the second, there is agar , whose melting point is 85 degrees Celsius and freezes at 31 degrees Celsius.

Refractory materials

So far we have seen that materials that cannot melt, that is, they do not have fusibility, are called refractory. In other words, these are those that resist very high temperatures without their state being altered . It is important to note that it is not easy to draw a dividing line between those who belong to this group and the others, although by convention those that do not soften when subjected to more than 1600 degrees Celsius are considered refractory.

In addition to this, for a material to be included in the refractory group, it must retain its structure and resistance despite the high temperature. Depending on the operation carried out, they should not break due to a sudden change in temperature, their thermal conductivity should be low and they should be chemically inert.

Soldering tin has a high fusibility value

In mineralogy

In the field of mineralogy , fusibility was studied by the German Wolfgang Franz von Kobell (1803-1882), who developed a scale with seven levels known as the Kobell scale .

Each level has a reference mineral. At the first level of the Kobell scale, antinomite or stibnite appears, whose approximate melting point is 525 °C . In the successive levels, from highest to lowest fusibility, are natrolite (with a melting point of about 800 °C ); almandita or almandine ( 1050 °C ); actinolite ( 1200 °C ); orthose or orthoclase ( 1300 °C ); bronzite ( 1400 °C ); and quartz (considered infusible ).