Cogeneration leads to a reduction in polluting emissions.

Cogeneration is the process that allows the simultaneous production of electrical and/or mechanical energy together with useful thermal energy . In this way, the generation of heat and electricity (CHP) can be achieved from a primary source.

Generally, a cogeneration plant is made up of turbines and reciprocating engines that make it possible to transform the energy present in a fuel into mechanical energy with waste heat. Thereafter, mechanical energy is usually converted, thanks to an alternator , into electrical energy , while heat recovery can be achieved in different ways.

Features of cogeneration

Cogeneration is part of what is known as the circular economy , which is based on taking advantage of waste and optimizing resources, also reducing the consumption of raw materials.

While in conventional power plants the thermal energy produced by combustion ends up dissipating into the atmosphere, in a cogeneration plant the exhaust gases are used to heat water thanks to its high temperature. This use occurs in a recovery boiler that produces steam, which can be used for the production of electricity or in other productive processes.

Cogeneration is typically carried out in industries that operate by producing high heat, such as the chemical sector and the food industry. However, in recent years it has also reached buildings of different types (health centers, sports centers and even homes) and swimming pools with air conditioning systems, for example.

Due to its characteristics, the paper industry can take advantage of cogeneration and even trigeneration.

Necessary equipment

A plant aimed at cogeneration of electricity must have some type of equipment to promote combustion . This may be a steam or gas turbine or a reciprocating internal combustion engine .

These machines make it possible for the fuel energy to be transformed into mechanical energy (and then into electrical energy), generating exhaust heat that is also used. Said use means that thermal energy, instead of being dissipated into the environment or a body of water, is used for different purposes.

In the case of cogeneration with steam turbines , the machines can run on natural gas, coal , biomass or other fuel to promote the transformation of the energy present in the steam into mechanical energy. If cogeneration with gas turbines is used, natural gas is used to produce combustion.

Cogeneration with internal combustion engines , meanwhile, allows the chemical energy present in a fuel to be converted into electrical energy (obtained through an alternator that is coupled to the shaft) and thermal energy (released as hot water and gases exhaust).

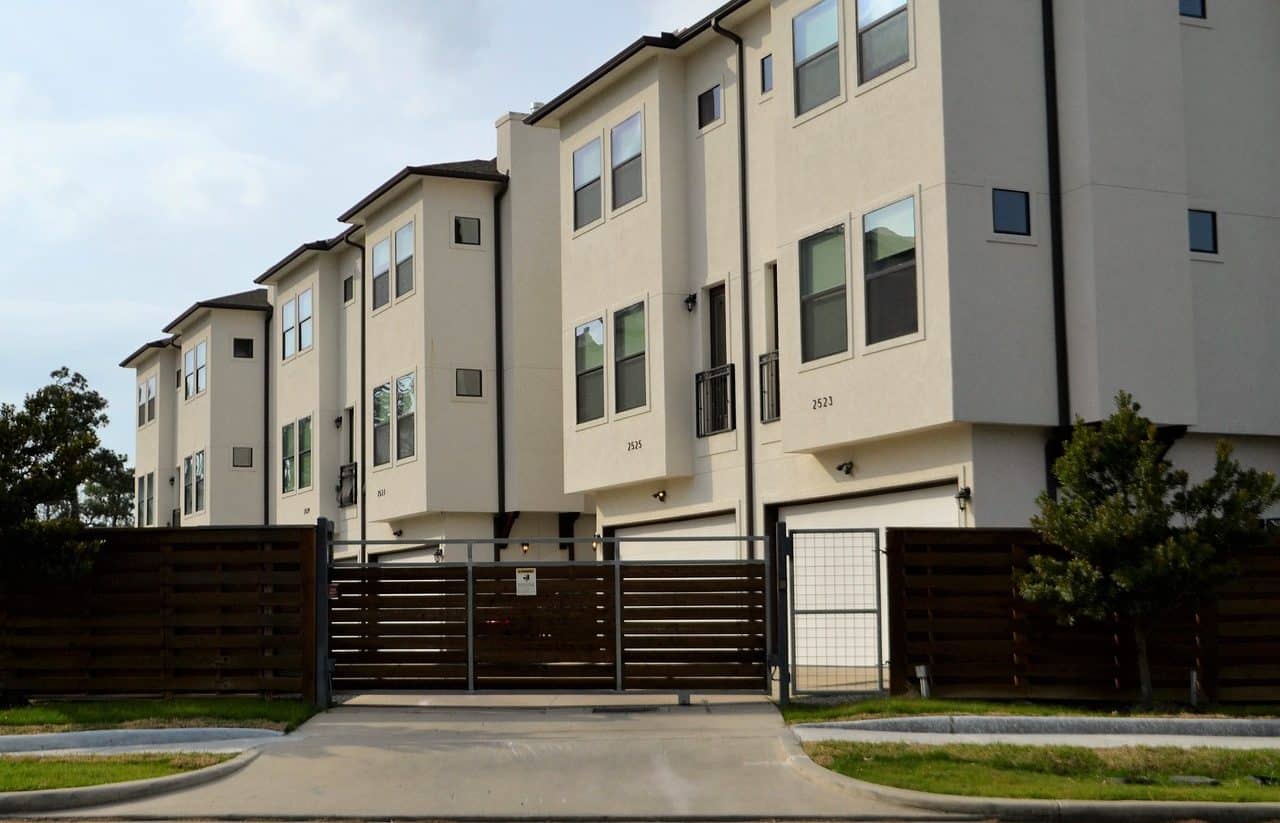

Small-scale cogeneration can be developed in hospitals, climatic pools and housing complexes.

Benefits of cogeneration

Cogeneration offers several benefits. As we already indicated, it allows the use of thermal energy that, with other forms of electrical energy generation, ends up dissipating. This avoids the need to generate it again through the use of a steam boiler.

According to data from the Spanish Cogeneration Association , this method enables savings of 40,000,000 cubic meters of water and 14,000,000 barrels of oil per year thanks to the optimization of energy efficiency , thereby contributing to sustainable development and minimizes environmental impact. Another consequence of increased efficiency is a reduction in costs for companies.

Unused heat, on the other hand, causes thermal pollution . This happens if a human-developed process causes a harmful or unwanted increase in temperature. With cogeneration, heat is not dissipated or wasted.

Another advantage of cogeneration is that it provides greater security and autonomy because it diversifies the sources for obtaining electrical energy and thermal energy . The electricity supply, in this framework, is more stable and can adapt to demand needs.

Cogeneration is usually linked to so-called distributed generation , which is based on the production of electricity through the use of small sources located in areas close to the consumption site. As cogeneration occurs next to the production center, the electrical energy obtained is not transported to another place, reducing inefficiency and losses.

The trigeneration

As we already indicated, cogeneration consists of producing mechanical and/or electrical energy with useful thermal energy in the same process and starting from the same energy source. When cold generation is added to the procedure, it is called trigeneration .

In trigeneration, therefore, electricity, heat and cooling are produced simultaneously . Cogeneration is generally combined with an absorption cooling system .

It can be said that trigeneration goes one step further than cogeneration in the search for energy efficiency. The cold water obtained can be used for air conditioning or used in different industrial processes.

As an example, we can mention that, in November 2023, Promisol and Promigas completed the inauguration of a trigeneration plant for the Colombian paper company Unibol SAS . The development, installed in the municipality of Soledad (department of Atlántico ), required an investment of 9.5 million dollars .