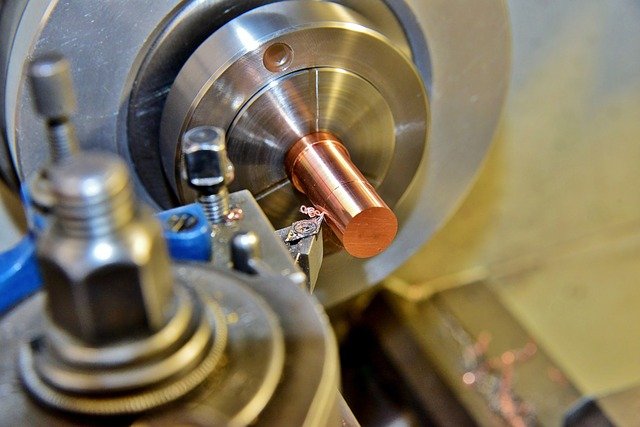

Turning is a cutting process.

Cylinder is the act and result of cylindering . This verb ( cylinder ), in turn, refers to compressing an element using a roller or cylinder , according to what is indicated by the Royal Spanish Academy ( RAE ).

Generally, cylindering is associated with the cutting process that is carried out with the objective of achieving a reduction in the diameter of a certain piece. Thanks to cylindering, the object is made more compact or smooth since part of its material is eliminated.

Displacement characteristics

Several similar operations are called cylindering. The notion may refer to the action that is developed with rollers so that a plate becomes concave ; to the procedure carried out with a lathe to minimize the diameter of a bar ; or the modeling of a cylinder of revolution , for example.

At a general level, cylindering consists of giving something a cylindrical shape or generating a concavity . A rolling machine rotates the rollers or parts that must move to achieve the desired reduction. It is possible to differentiate between sheet metal turning , plate turning and lathe turning .

Factors to take into account

When the cylinder diameter is specified with a lathe to limit the diameter of a material , several issues must be considered. The goal is to achieve a specific finish that must have certain particular features.

The operation requires the formation of a right angle between the cross slide and the tool. Another type of angle would result in a larger contact surface, with greater wear and heating.

It is essential to take into account how much material is removed in each pass. In addition, the type of cutting tool and speed must be analyzed since these variables affect the turning result.

Turning can be carried out with a lathe.

Importance of cylinder capacity

Cylinder is key in multiple industrial areas. Thanks to it, the exact surfaces and dimensions of many parts are obtained, which helps reduce failures in different machines.

On the other hand, metal parts with the geometric finish provided by this process are needed to optimize aerodynamics and vehicle support . Sheet metal rolling, in turn, has numerous applications in industry and commerce .

The displacement, another concept

It is important not to confuse displacement with cylinder capacity . Although there is only one letter difference, both notions refer to different issues.

The idea of displacement allows us to name the capacity of the cylinders of an engine. Displacement can be calculated by examining the distance the pistons travel and the number and diameter of the cylinders.

Also known as engine displacement , displacement is linked to power . Typically, the larger the displacement of an engine, the more power it has and the more fuel it consumes. At the other extreme, a small displacement engine offers limited power and consumes little fuel.

As you can see, displacement is related to the cylinders of an engine . Turning, on the other hand, is a cutting process for finishing a piece.