Calibration requires the existence of previously stored values with which to compare the current ones.

The concept of calibration refers to the act and consequence of calibrating , a verb with several meanings. Calibrating can consist of calculating or determining the caliber of an element; adjust an instrument with respect to a reference; or value or estimate something.

Value comparison

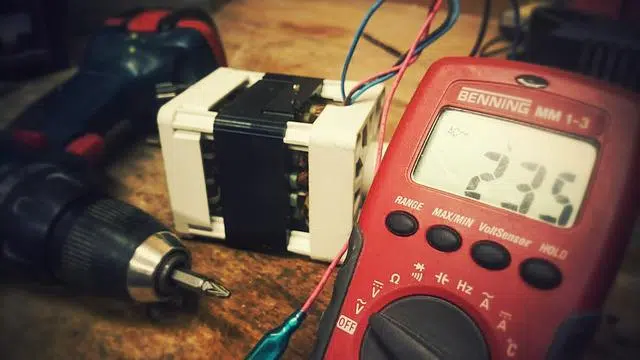

Calibration, therefore, can lie in the comparison of the values obtained using a measuring instrument with the measurement that corresponds to a reference standard . In this way, the calibration of an instrument is carried out by appealing to another one of greater precision that offers values that can be verified.

By comparing what the instrument being calibrated indicates with the value of the reference standard, you can know how accurate the artifact in question is. The higher the calibration frequency, the greater the accuracy of the measurements, since this process allows the necessary adjustments to be developed.

Calibration is generally carried out under controlled conditions . This means that temperature , humidity and other variables are manipulated so that they do not affect the measurements. We assume that the values taken as reference have been stored under the conditions that we must respect when performing the calibration.

Dust or dirt in general are enemies of calibration in many cases, especially when they can affect the correct functioning of mechanical parts or the electrical contact of an electronic device. In fact, they are often the cause of many malfunctions that lead to an inevitable calibration to confirm the differences with the correct values. Once this check is done, we must proceed to carry out an appropriate cleaning , to finally repeat the calibration process until the results are acceptable.

Usefulness of calibration

There are many reasons that may make a calibration necessary. If an instrument's measurements are questionable, for example, calibration is essential. Calibration may also be unavoidable if the device has been subjected to a sudden or large change in temperature, if it has been hit, or if it has been used for a long time .

Scales , micrometers , dial gauges , tachometers , ammeters , microscopes and thermometers are some of the devices that must undergo calibration to remain reliable.

Touch screens and controls

Although touch screens are very common today and their technologies have advanced considerably in recent decades, the first versions were less sophisticated and required more frequent maintenance by the user. Calibrating a touch screen can help us detect imperfections in touch detection in certain parts of its surface, which may be due to the presence of dirt particles, excessive wear or internal damage.

Calibrating video game controllers serves to confirm problems with their sticks .

Generally, throughout this process the user must touch different parts of the screen, individually or simultaneously, and the system advances from one step to the next when it correctly detects each action. Video game controllers, and even some television controllers, usually include technologies for detecting movement in space and rotation by the player. This has a certain margin of error , and that is why calibration is necessary, to ensure that our device responds correctly even when our experience is not completely satisfactory.

The joysticks , which even in our language are usually called sticks , are parts of the controls that are generally delicate or susceptible to great wear and tear , particularly if they are used for frenetic action titles, such as fighting. Games that require rapid and extreme movements consecutively for several minutes can cause problems in these pieces. Their calibration usually consists of moving them towards the corners and then performing a complete rotation.